The Elegoo Mars 2 Pro is a compact 3D resin printer that produces incredibly detailed 3D prints that almost look injection moulded. And despite its impressive build quality it is reasonably priced at around £250 or $250.

It almost magically turns liquid resin into 3D models using UV light. But I’ll try and demystify the process with an introduction to resin printing. Then after covering the basics of the machine itself and the optional Mercury Plus wash and cure station, I’ll print a variety of models to see just how well the printer performs and how easy it is to use.

I will compare resin printing to filament-based printing, so you might want to check out my earlier articles that introduce that technology if this is new to you.

Introduction to resin printing

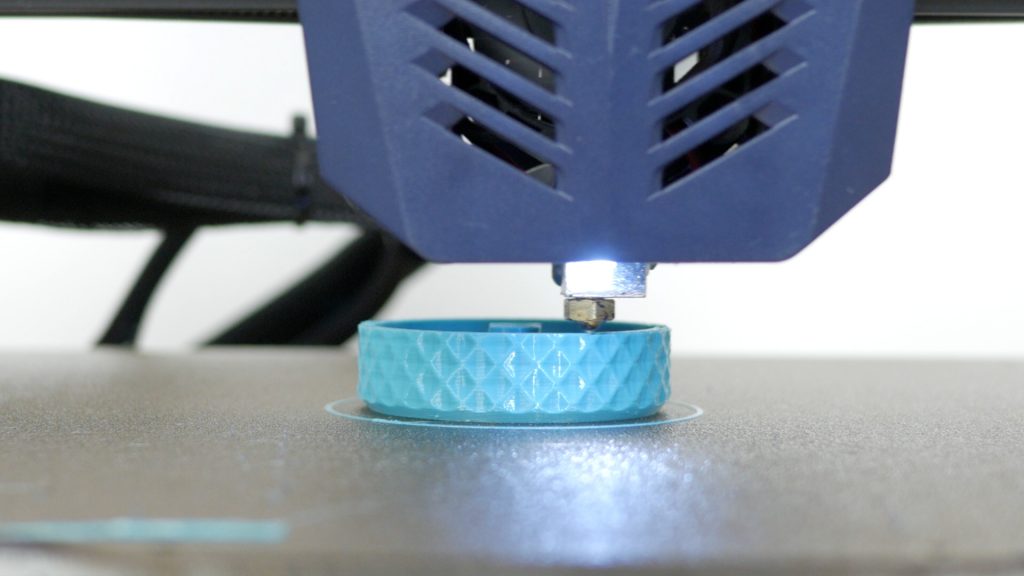

I’ve reviewed a few filament or FDM printers that melt rolls of hard plastic filament and squeeze the melted plastic out of a small nozzle that moves around the printer bed, building up models in layers. Once you see a printer like this in action it’s quite easy to understand what’s going on.

Resin 3D printers also build up models in layers, but that’s where most of their similarities end. And even seeing them print, it’s not at all obvious what’s going on.

Liquid resin sits in a resin tank on top of what is essentially a smartphone screen. The bottom of the tank has a thin clear plastic film made of FEP or Fluorinated ethylene propylene which is a non-stick material like Teflon. The models are printed upside down with a build plate that lowers on a single axis into the resin tank.

The build plate starts at the chosen layer height above the FEP film. UV light is shone through the LCD screen which displays each layer as a mask. The resin is cured or hardened by the UV light, but only in the unmasked areas. The build plate then pulls this hardened layer off the non-stick FEP film and then moves back down, this time one layer higher, building up the model one complete layer at a time. There are far more expensive SLA printers that use a laser to draw the layers, but the Mars 2 Pro, like most common resin printers, is more accurately referred to as a DLP or Digital Light Processing LCD resin 3D printer.

The main advantage of resin printers is the incredibly fine detail they produce. They have much higher horizontal resolution compared to FDM printers, which have to physically move a print head around. The horizontal resolution is based on the resolution on the LCD panel and for the Mars 2 Pro is 0.05mm.

And the vertical layer height is finer too. 50 microns or 0.05mm is a typical layer height, but they can go down to 0.01mm. Even at 0.05mm the layer lines are pretty much invisible and together with the horizontal resolution parts can almost look injection moulded.

Which all makes resin printers much better suited to smaller prints or prints with lots of detail. Another advantage of DLP resin printers is that print times are only a factor of layer height, since the complete build plate sized layer is processed at each layer height.

Which is handy if you want to print multiple parts for example and can make them faster than filament-based printers.

They’re also a little more compact than FDM printers, and arguably they’re simpler to print with. All being well, you simply pour resin into the tank and print. But I’ll come back to this in the review.

There are a few disadvantages though. Typically they have far smaller build volumes than similarly priced FDM printers, and the prints do require post-processing which can be messy.

You generally need to wash off excess resin using IPA alcohol and then you need to fully harden them in UV light – either in sunlight or ideally in a curing station.

The resin does have an odour so you should use the printer in a well ventilated room and you do also need to handle and dispose of uncured resin with care taking note of the warnings on the bottle. If there’s a chance of resin getting on your hands you should wear gloves. I’ll provide a link to a useful video that covers safety using resin printers in the description.

You also have less choice of resins to print with compared to FDM printers, which can also print engineering grade materials like Nylon and Polycarbonate. So for structural parts, an FDM printer may still be a better choice. But I will be using a supposedly stronger ABS like resin from Elegoo in this review and also try mixing this with a tougher resin from Siraya Tech. So we’ll see what sort of results we can expect shortly.

Printer overview

In the box you get the printer itself with its external power supply and a decent selection of accessories including some masks, resin straining filters and side snips. There’s also a very nicely presented user manual.

No assembly is required – a very nice bonus compared to most FDM printers I’ve tested. The only thing you need to do is remove all the protective wrap and install the rubber seal around the base of the lid.

The machine is very well built, not something I was expecting at this price point. It weighs just over 6kg and has a metal base with four adjustable levelling feet. You can see its dimensions – it doesn’t take up much space.

The Mars 2 Pro has a 6.08” monochrome LCD screen with a 1620 x 2560 2K resolution. The monochrome LCD screen has a longer life than earlier printers with RGB screens and the mono LCD screens enable faster printing too with better UV light transmission.

The printer build volume is 129mm x 80mm with 160mm maximum height. Dividing the horizontal dimensions by the resolution of the screen gives the horizontal resolution of 0.05mm: 129mm divided by 2560.

The 12V 4A power supply plugs in around the back where there’s also the power switch.

Around the front there’s the 3.5” touch screen and a USB port to use with the supplied USB thumb drive or your own.

To set up the printer, power it on and attach the build platform, tightening it to the Z axis pillar with the knob. The build platform is also well constructed and the build plate has a sand-blasted slightly textured finish to provide better adhesion. It sits on a ball joint which you need to loosen with the supplied allen key. Keep hold of it just in case and make sure it can move freely ready for levelling.

The build plate needs to sit exactly parallel to the bottom of the resin tank. It’s a pretty straightforward process and it doesn’t need to be done every time.

Remove the metal resin tank after loosening the two knobs, and slide in a piece of paper. Then tap Tool | Manual and the Home icon. Square up the build plate to the front of the machine and with slight pressure on it, tighten the front ball head bolt first and then the second – in that order.

You need to be able to remove the paper without too much resistance. If there is, change the Z axis movement to 0.1mm and press the up arrow once. Tap Back and then tap Set Z=0.

That’s levelling done. If your resin tank is clean you could use this to more accurately set the level since you’re then using the actual FEP film thickness rather than estimating the thickness with a sheet of paper. But I had no trouble just using the paper and you’ll usually have resin in your tank.

Tap the 10mm axis movement and tap up to move the build plate out of the way. Slide the resin tank back in and tighten the bolts.

Shake the resin bottle and fill the tank around a third of a way. Put the cover back on, insert the USB drive and select the Rook.ctb file and tap print. The LCD screen displays a thumbnail of the print files and the screen is quite responsive. It is quite dim though and you do need to look directly at it to see the icons.

All being well, a couple of hours later you should have two Rook chess test pieces printed. You can’t see what’s going on for at least 30 minutes, but you should hear a slight popping sound as each layer is released from the FEP film. You can tap pause which will raise the bed to check progress – and also allows you to top up the resin. But if you’ve followed the basic setup these pieces should print successfully.

Cleaning and curing

Before your print is ready to be used, you need to first wash off the excess resin. Start by using the drip attachment to hang the build plate over the resin tank. It’s a bit of a juggling act, removing the build platform, screwing it onto this drip attachment and then hooking that back on the Z axis, without any drips of resin falling outside the tank. But you get used to angling it slightly to avoid this. I put the lid back on and leave it a while for as much resin to drip off as possible if I’m not in a rush.

I’m using the Elegoo Mercury Plus Wash and Cure Station to post process the prints, and quite honestly if you’re going to get a printer like this, I’d budget for one of these too. You don’t absolutely need one since you could wash the prints off in a tub with some IPA alcohol and a toothbrush and leave them out in the sun to fully cure or buy a cheap UV lamp if you live on Dartmoor. In this review I’ll be using this wash and cure station.

Fill the cleaning bucket with 99.9% IPA which you can pick up relatively cheaply on Amazon or eBay. I’d recommend buying at least 5 litres to get started, which I bought for around £15. Fill the container to the 2.5L mark and make sure the curing turntable is removed before placing the bucket in the machine.

Detach the build platform from the drip attachment and then move it over the wash bucket avoiding any drips. Slide in the metal adjustable bracket and hook this onto the upright pillar. Adjust the bracket so the build plate sits in the alcohol.

Put the lid on, choose the wash cycle and run it for a few minutes, which spins a magnetic rotor at the bottom of the bucket which agitates the alcohol. The IPA gets quite cloudy after you’ve used it a few times, but it still does the job. And you can get more use out of it when it becomes less effective by letting any cured resin sink to the bottom overnight, and then decanting it through one of the included filters.

Remove the build platform and use the metal scraper to remove the print off the build plate over some paper towel. The test models are very hard to remove – I had to give them a short sharp strike with the scraper to release them. But most prints come off far more easily.

The Rook model doesn’t have any supports which I’ll discuss shortly. This is unusual for resin prints where supports are the norm.

If your print has supports it’s probably easier to remove them now before hardening them in the cure station. Some will just pull off with your fingers or use the side snips for more stubborn ones.

Remove the bucket from the machine and insert the curing turntable. You can remove the brown protective film. Place the prints on the turntable, put the lid back, choose the Cure setting and start off with 2 or 3 minutes. The magnetic turntable rotates slowly and the vertical pillar shines UV light to quickly cure the print. The manual doesn’t provide much information on timings, but small prints don’t take long – start with a couple of minutes for smaller objects. If you remove them and they’re still a little tacky give them a little more time. Too much time in the curing station can make them more brittle. Conveniently both the cure station and the printer use the same AC adapter.

If your supports leave any marks, you can use some sandpaper to tidy them up.

Printing results and slicing your own models

Apart from a little damage removing them from the build plate, the Rook models look very impressive in the grey Elegoo ABS-Like resin I’m using. This resin is meant to be tougher than their standard resin and since I like to print mainly functional parts rather I want the extra strength. And it’s about the same price too but it’s still a lot more expensive than rolls of filament – weight for weight it’s about twice the price. And since you need to add lots of supports for most prints there’s more wastage too. Not to mention failed prints.

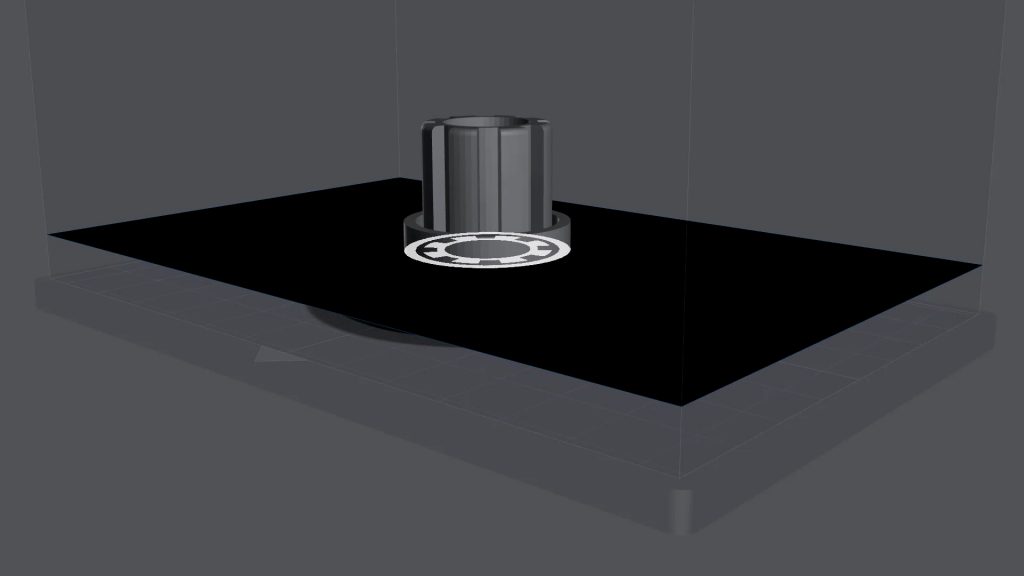

Which brings me nicely on to my next print. Our shower rail broke a while back so I designed a replacement bracket in Fusion 360 which I’ve previously printed on an FDM printer. To convert the model into something the printer understands you need to slice it, just like with a filament based printer.

This takes the 3D models and divides it into slices or layers that the printer understands, based on your chosen layer height. Elegoo includes Chitubox which is fairly easy to use, although to use the latest version I also had to update the firmware on the machine. I’ll link to instructions on how to do this below.

There are plenty of tutorials online on how to use Chitubox and again I’ll link to a couple I’d recommend watching below. But I’ll cover some basics. Click on Settings and add the Elegoo Mars 2 Pro. For most Elegoo resins you shouldn’t need to change anything but for their translucent resins you’ll need to increase exposure times – that is how long the UV light comes on for for each layer. You can set that up here referring to this table.

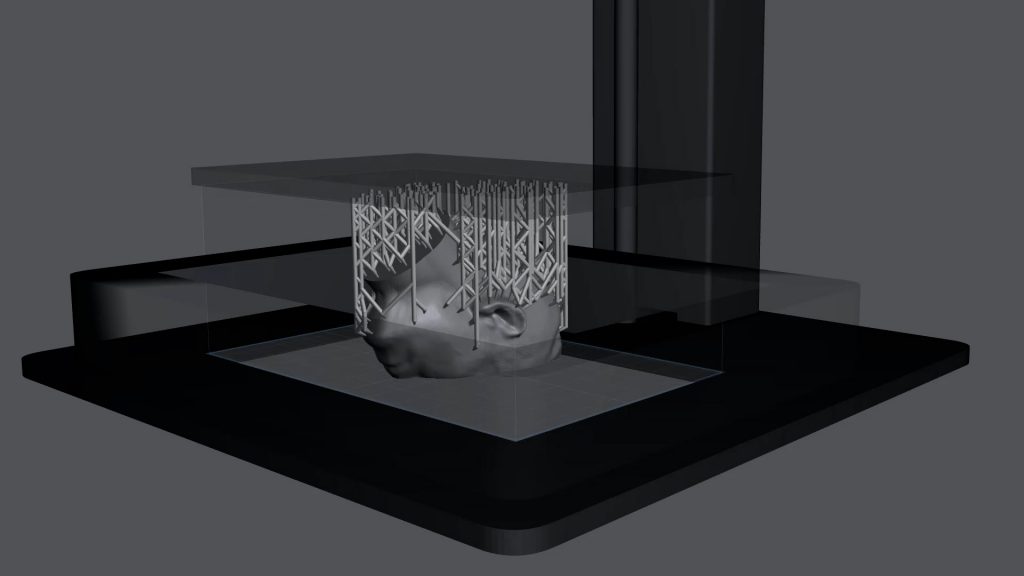

You do need to get your head around how resin printers print when preparing your models. The most important thing I found is to make sure the start of the print is anchored well to the build plate. Each cured layer is pulled off the FEP sheet by the previous layer. But although it’s non-stick, it can still require a fair bit of force to pull this layer off especially if it has more surface area. This can result in either the model being pulled off the build plate or more likely any supports that aren’t beefy enough being torn apart, which leaves the cured layer stuck to the FEP sheet in the bottom of the resin tank. Which is a failed print and worse still, you have to clean out the tank which is a really messy and time consuming job.

This model can’t be printed straight off the build plate since there’s too much suction between the first few layers and the subsequent layers. A large flat base like this would also tend to become slightly splayed at the bottom, referred to as Elephant’s Foot. And the model would be very hard to release off the build plate.

It’s recommended to tilt the model between 30° and 45° to limit overhangs and large suction forces, making sure the features that are important face away from the bed and therefore the supports. Supports are required to both ensure the print doesn’t droop, but also to avoid printing any parts of the design in mid-air.

How you orient and support the model will vary for each print. Here I’m not too worried about the bottom of the bracket, which will sit against the wall.

After adjusting the orientation of the model with the Rotate tool, you then click on the Supports tab. In the support Settings select Heavy supports and +All to automatically add supports.

Switch back to the File List tab and click Slice. You’ll get an indication of the print time which is always at least 30 mins quicker than the actual print time in my experience. And the cost in resin if you’ve entered the correct price and currency in Settings. There’s also a preview of the layers that will be sent to the LCD screen. A handy little feature here is the “Show isolated island layers”. Give it a minute or two and it’ll highlight in red any layers that will be printed in mid air – something you don’t want. Even if this doesn’t result in a failed print, it will mean resin stuck to your FEP sheet which means cleaning the resin tank before your next print. Save the .ctb file to your thumb drive and print.

Even if the print’s successful, use the plastic spatula or a gloved hand to feel the bottom of the FEP sheet for any stuck bits of resin. If there are, you’ll need to clean the tank. This is my least favourite part of resin printing but I’ll quickly run through it since you will have to do it at some stage.

You can run Tools | Tank clean which will send by default 15 seconds of unfiltered UV light to attempt to collect any small bits of slightly cured resin floating around the bottom of the tank, together with the failed layers into one thin slab of resin that you can peel off in one go. Theoretically you could remove this without emptying the tank, but it’s not easy. You don’t necessarily have to run the Tank clean if you’re going to empty the resin tank and clean it out anyway.

You really need a funnel together with the supplied paint filters. I ordered 150 filters off Amazon which included this silicone funnel. Open your resin bottle and insert the funnel and filter. Carefully remove the resin tank and slowly pour the resin via the tank’s corner spout back into the bottle. Use the plastic spatula for the last bits of resin.

You can push lightly up with your gloved finger to raise the edges. Then use IPA and some soft paper towel or microfibre cloth to completely clean the tank. I like to have some degreaser wipes to hand to keep my nitrile gloves clean. And I’ve found Scott’s Workshop towels to be very absorbent and soft enough not to scratch the FEP sheet. Microfibre cloths would be better but I save them for when I’ve got rid of all the resin.

And I use the microfibre cloth on the underside of the FEP sheet too. You can also use the wash station to clean the tank using the cleaning basket.

When it’s completely clean, I gently also clean the LCD screen with a microfibre cloth and place the tank back in the printer. A little camera air blower is handy for making sure no dry particles remain in the FEP sheet.

Coming back to this model, even with Heavy supports Chitubox’s default support settings are too conservative for a model like this. There’s too much suction from the FEP sheet for these layers just above the anchoring supports which results in the supports getting pulled apart and the print failing. The most obvious solution is to add more supports. But I also had prints stuck to the FEP sheet with other models

So I attempted to improve the release of the FEP sheet by rubbing in some PTFE lubricant with a dry soft paper towel – a tip I saw in a YouTube video from Bluebrain. I still had issues with prints sticking a little too well to the FEP sheet so I tried replacing the FEP sheet – Elegoo provide a couple of spares and a step by step tutorial on how to do this.

Ultimately a combination of the PTFE tip and over-supporting models – especially more functional heavy weight models – did the trick and I’ve had no failures more recently.

I did note in Prusa’s instructions for their SL1 and SL1S resin printers they recommend not using IPA to clean the FEP sheet – possibly since it does too good a job – we still need the FEP sheet to release the print. They interestingly recommend cleaning the tank after every print and using only warm water and washing up liquid.

I would like to try some of EPAX’s Non-FEP sheets when I get a chance – which are meant to do a better job of releasing prints.

With this model you can either add manual supports, or up the 50% density to at least 75% for the auto supports. I still always go back and at least over-support the initial anchoring layers of the print.

This model ended up printing quite nicely and I installed it in the bathroom. Unfortunately it didn’t last very long – it snapped off a day later. It’s not a very scientific test, but even FDM prints from PLA+ lasted way longer. So I still needed to find something stronger for functional prints. I’ll come back to a possible solution shortly.

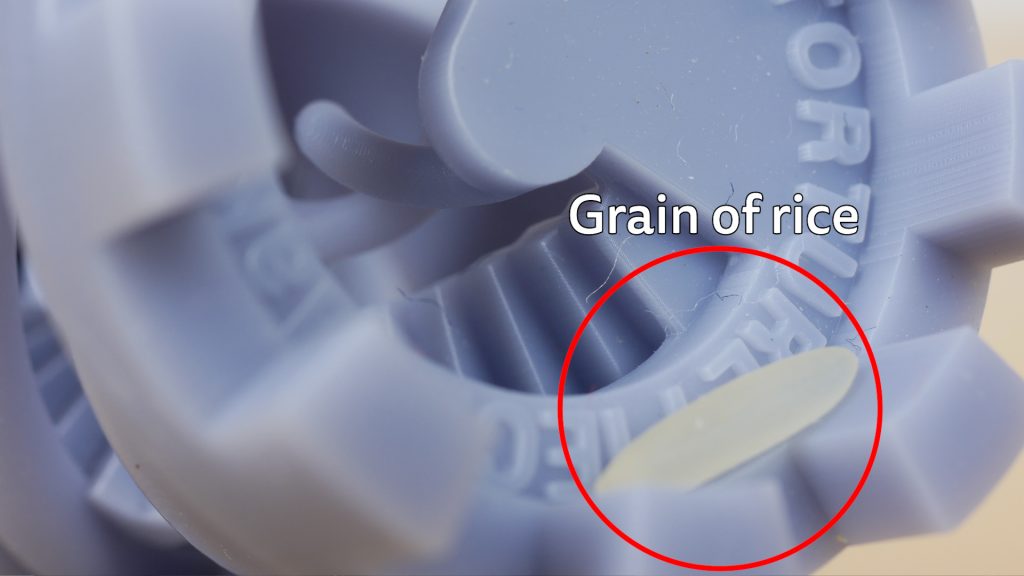

I stuck with the default layer height of 0.05mm and tried a few more prints. First off a couple of test prints. This AmeraLabs calibration print shows off the level of detail resins prints can produce – this is a little larger than my thumbnail. I also experimented with exposure times with the free Resin Exposure Finder on Github. You run a piece of gcode on the printer which prints a chart with exposure times from 0.5s up to 5s and then slice a small calibration square at the exposures you want to test.

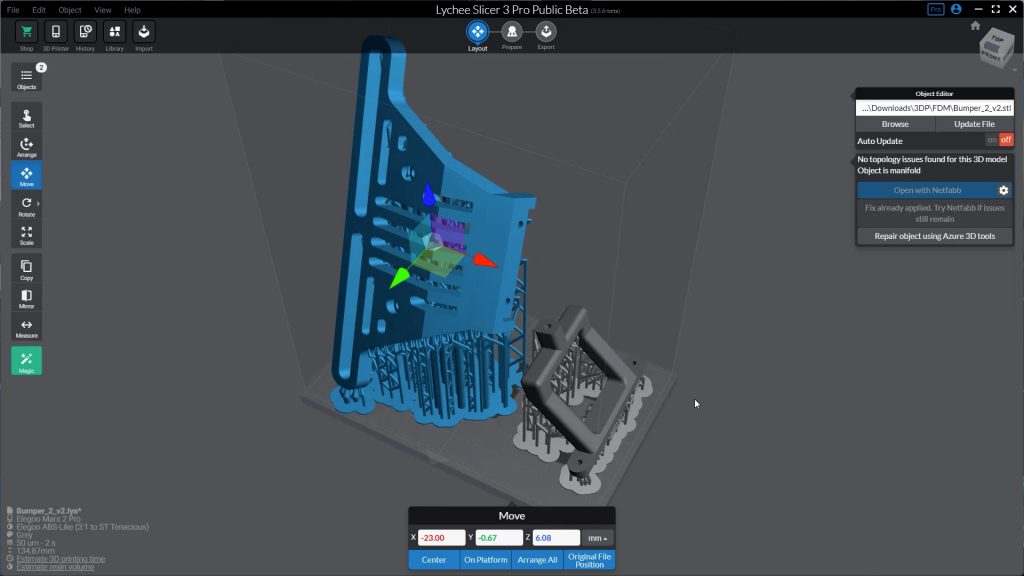

I found I could go a little lower than the default 2.5s – 2s gave slightly better results. And interestingly Lychee slicer uses 2s for this printer. Lychee slicer is an alternative to Chitubox and can still export .ctb files that can be printed off the Mars 2 Pro. I found it easier to use compared to Chitubox and it has more features in its free version. Although there is a 20s ad on the free version when you export a file.

I printed my final calibration print with auto supports in Lychee slicer. The 3D Benchy is a popular filament printer test. Here I halved its size but it still came out very good, with an amazing amount of detail. You can even read the tiny text on the back of the boat.

I hollowed out this model and added a couple of drainage holes at the bottom, so no resin gets stuck inside. Many models don’t need to be printed solid and resin slicers have the ability to hollow out your model, but Lychee Slicer’s implementation was the most intuitive.

Next I tried a miniature off the USB stick – there’s a few on there but I chose the Barbarian. Miniatures are a hugely popular use for resin printers. I could definitely do a better job taking some extra time with supports, but it came out pretty well and this is before any clean up.

My Garmin 1000 cycling computer’s power button has worn out so I printed out a replacement button off Thingiverse. This worked perfectly and although I’d printed this on my Prusa FDM printer before, it came out much better with the Mars 2 Pro.

This Lego minifigure came out nicely but I was a little heavy on supports as you can see around the back. But again you could sand some of those marks away.

I printed a belt buckle to see how much flex the Elegoo ABS-Like has. It came out quite nicely and there is plenty of flex, but it’s still brittle – the edge of the buckle broke after a few insertions.

Most of these prints took between 1.5 and 3 hours but I thought I’d try a larger print. I used PrusaSlicer to slice this model of a Bernie Sanders meme from ChaoCoreTech which I also hollowed out, although I forgot to add drainage holes. It’s a faff using PrusaSlicer but I’m quite familiar with the program and I found its autosupports quite good. You have to hollow out the model in Lychee Slicer or Chitubox, then add supports in PrusaSlicer, then export as an STL with supports and import back into Chitubox or Lychee to export to a .ctb file!

Still it came out looking very good, considering I spent less than 5 minutes adding supports.

And the supports came off easily but I did pull off one arm of his glasses a little carelessly.

Since I’d still like to use this printer mostly for functional prints, I started experimenting with tougher resins. There’s far less information about this online but I tried mixing the Elegoo ABS-like resin with Siraya Tech’s Tenacious resin which is tough and slightly flexible but also very expensive.

I tried a 3:1 ratio of Elegoo to Siraya Tech which brings the cost down, and should make for tougher prints with better impact resistance. I printed the exposure test again to confirm I didn’t need to adjust exposure times and went about printing two parts for the bumper of my son’s RC car which had broken off.

You can see how it’s easy to quickly start exceeding the size of the small build plate. But with some careful orientation I managed to fit both parts on.

I realised half way through this print that I hadn’t added enough resin, but one part of the bumper still completed. It’s a shame the printer has no sensor to alert you of the resin being low, like some more expensive printers have.

I haven’t done enough testing yet and I will need to experiment further with ratios, but parts do seem a little less brittle. I could probably use 100% Tenacious for the RC car bumper with its good impact resistance, but it’ll be harder to print and expensive. Siraya Tech also has their Blu tough resin which I may try at some point. But it’s also pricey and needs to be warmed up before printing and requires additional post-processing which all sounds like a little too much faff. And all these resins don’t have very good temperature resistance. But there are resins available like Phrozen’s TR300 that can resist temperatures up to 220°C which I haven’t tried yet.

Finally I used my phone’s front TrueDepth camera to make a 3D scan of my head.

Any iPhone with FaceID will work. Scaled down to 25% and hollowed out this came out pretty well and I now have a slightly eerie memento of this review.

The printer is fairly quiet in operation. There is a fan running and the sound of the build plate moving up and down but it’s probably the popping sound of the print lifting off the FEP sheet that you hear the most (you can hear how the noisy the printer is in the accompanying video). I can still work with it printing less than a metre away without too much trouble. And although the resin does smell, the printer has an active carbon filter built in which together with the lid means it’s not really noticeable most of the time. Worryingly this carbon filter doesn’t appear to be user-replaceable though.

A slightly more substantial and tighter fitting rubber seal on the lid might improve things further. I’d also really like the lid to be hinged so you don’t have to find somewhere to put it. I could probably install a handle on the top to at least make it removable one handed. Ideally the wash and cure station would also have a hinged lid.

There are quite a few consumables you need for this printer or any resin printer as well as the resin itself. The FEP sheet will need replacing if it gets scratched or becomes cloudy. You definitely don’t want it tearing, since that could be very messy. As I mentioned the printer comes with 2 spare sheets and you can get a replacement set of 5 for around £20 or $20. Another option is some spare resin tanks which already have the FEP sheet installed and come with lids so handy if you want to print in different resins without having to empty and clean the tank.

The LCD screen is also considered a consumable but should last a fair bit longer although I couldn’t find any details on how long it should last with this printer. Prusa quote 2000 hours for their mono LCD screens. These aren’t too expensive – they’re currently listed at just over £30 or $30 on Amazon.

You also need IPA, gloves and filters and silicone slap mats are pretty handy too. They’re cheaper if you buy them as pet food mats like these ones from AmazonBasics. So overall resin printers are more expensive to run than FDM printers, even though the upfront cost might be a little cheaper.

Conclusions

It’s difficult to find many faults with the Mars 2 Pro from Elegoo. Nearly everything about it is well built, from the base to the resin tank to the build platform. This is especially impressive considering its price. Although I really would budget in the Mercury Plus cleaning and curing station or something similar, to try and minimise contact with the resin and speed up post-processing. You do need to be very careful with the resin and follow all the safety precautions, but I wouldn’t let this put you off trying resin printing.

And that’s mostly because it’s hard not to be impressed at the quality of prints it can produce. The only real issues I had were more related to the rather steep learning curve. Even with plenty of experience of 3D printing with filament based printers, it did take quite a few failures to understand how to get successful prints. You do need to spend a bit of time understanding the slicing software and most importantly supports. The printer itself is quite easy to use. And hopefully this video will help you get started.

If you’re going to go with auto-supports I’d try Lychee Slicer – I got much better results than from Chitubox – at least for the larger more functional models I like to print. But I’d recommend choosing the medium support setting and sliding the support density to high – at least to start off with. Also run the Islands Detectors and let it add supports to all islands. It’s much better to have successful prints even if there’s a little more print tidying up to do, than to have to repeatedly clean the resin tank.

I would like to see a slightly higher quality FEP sheet that didn’t require manually coating with PTFE if at all possible, which I’ll come back to in a minute. And I don’t like the active charcoal filter not being user-replaceable. Ideally it’d be far more convenient if the covers for both the Mars 2 Pro and Mercury Plus were hinged in some way. Finding somewhere to put them is not always easy. And a resin level sensor would be a nice addition too.

Depending on what you want to print, you might find the small build volume plenty, but I found it a little restrictive compared to what I’m used to with FDM printers. I’d be interested to try a resin printer with a bigger build plate at some point.

In my initial testing with more functional prints, I’ve found resins a little more brittle compared to materials I can print with on FDM printers, even with so-called ABS-like resins and mixing in expensive specialist resins. But I look forward to experimenting with this further, testing a few more engineering grade resins. Even if it’s messy, it can be fun playing the chemist, combining resins to achieve the exact mechanical properties you need for a project.

Resin printing does seem to be a few years behind FDM printing in some ways, especially for these more structural parts rather than miniatures and props which it excels at. But I think this will change rapidly as printers and resin technology advances, and prices come down.

If you want to dip your toes in resin printing though, I think this printer is an excellent option. There is also the Mars 3 that Elegoo has just released. It has a higher 4K resolution and a slightly larger build volume. And it has an upgraded FEP 2.0 sheet that I’d like to try on the Mars 2 Pro, as I alluded to earlier. But it’s their non pro version and doesn’t have the built in carbon filter. And it’s more expensive.

Don’t forget to take a look at my YouTube video at the top of the page, and subscribe to my YouTube channel where I’m releasing videos every week on the latest technology and how to get the most out of it. If you tap the bell icon when you subscribe you’ll get a notification as soon as I release a video, and there’ll be a link to my site here for the written article. YouTube is also the best place to leave a comment. I read all of them and respond to as many as I can!

Elegoo Mars 2 Pro: https://amzn.to/2Zl0auH

Elegoo Mercury Plus 2 in 1 wash and curing machine: https://amzn.to/3xiF5NQ

Elegoo Mercury Plus 2 in 1 wash and curing machine V2.0: https://amzn.to/3DSUw1Y

Elegoo Mars 3: https://amzn.to/3CQ1H9N

Elegoo ABS-Like resin: https://amzn.to/3r7znh0

Siraya Tech Tenacious resin: https://amzn.to/3oZ9PzS

Elegoo spare resin tanks (2): https://amzn.to/3l7WIeC (aluminium) https://amzn.to/3nOpB0V (plastic)

Elegoo FEP sheets (5): https://amzn.to/3FGQf1W

Elegoo replacement screen: https://amzn.to/3p0GK6S

IPA 5L: https://amzn.to/3cLOdRG

Silicon mats (2): https://amzn.to/3nJEbH3

Funnel and filters: https://amzn.to/3FJwhDJ

Nitrile gloves: https://amzn.to/3r4Jpz8 (I’ve found these cheaper locally – in the UK: Toolstation). These are the ones I use for cycling repairs so are probably tougher than you really need.

Heavy duty wipes: https://amzn.to/30QUFoo

Soft paper towels: https://amzn.to/3CIvVeI

Leave a Reply